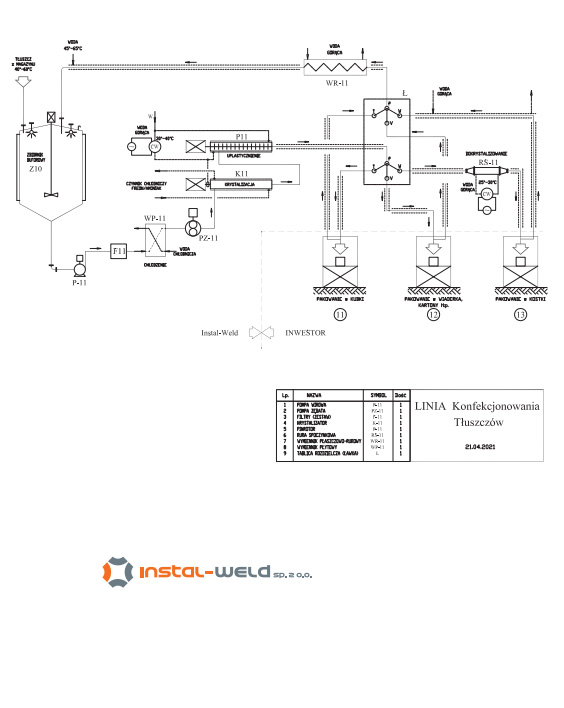

A typical line consists of:

- liquid fat buffer tank upstream the process,

- rotodynamic pump feeding the crystallization line,

- cooler adjusting the temperature of fat before crystallization,

- set of filters protecting the product and equipment,

- high-pressure pump directly supplying the crystallizers,

- crystallizers (SSHE - scraped surface heat exchangers),

- pinrotor using which one can adjust the consistency and plasticity of the finished product,

- resting pipe in the case of packing the finished product into cubes.

The heart of the line is the crystallizer in which fat is cooled and crystallized. The scrapers are mounted on a heated sha[ and are pressed against a cooled cylinder using centrifugal force as the shaft rotates. This ensures very efficient scraping of crystallized product from the inner surface of the cylinder regardless of the product consistency. The offered crystallizer ensures high crystallization capacity, continuous operation, low electricity consumption and easy maintenance.

Crystallizer technical data:

Electric power: 7-21kW depending on the line configurationRefrigerant: ammonia, freon

Working pressure: up to 50 bar

Capacity: 1,500-3,000 kg/h per crystallizer depending on the type of product.

Download the offer [PDF]